In the fast-growing Internet of Things (IoT) industry, speed, quality, and scalability determine whether a hardware product can survive the competitive market. From PCB design to SMT assembly and final testing, every step must be optimized for rapid iteration and stable large-scale output. As more companies search for trusted partners who understand SMT meaning and full-process manufacturing, PCBasic stands out as a professional PCB assembly supplier capable of supporting both fast prototyping and high-volume production.

Why IoT Hardware Requires a Specialized PCBA Partner

IoT hardware is unique: devices are getting smaller, more power-efficient, and more densely packed with sensors, wireless modules, and embedded processors. This leads to three manufacturing challenges:

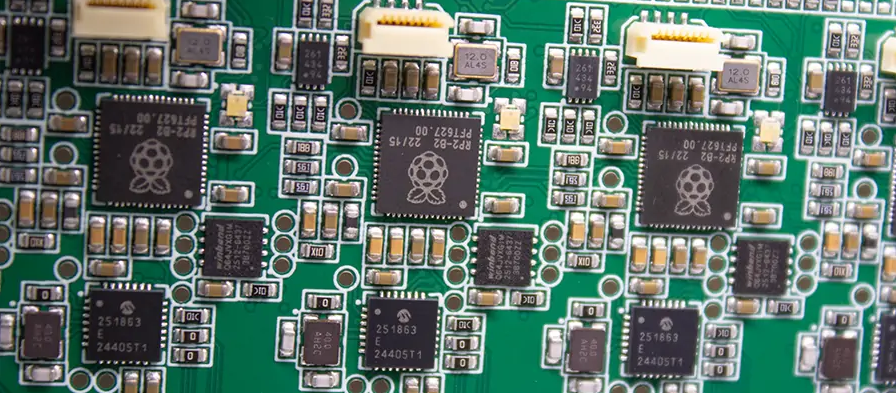

1. High Component Density & Miniaturization

IoT devices rely on tiny components such as 01005 resistors, fine-pitch QFNs, BGAs, LGA modules, and RF chips. These require advanced stencil design, high-precision SPI inspection, and nitrogen reflow profiles to ensure reliable solder joints.

2. Rapid Prototyping Cycles

IoT products often iterate quickly—sometimes weekly. Engineering teams need:

- Fast PCB fabrication

- Same-day or 24-hour SMT prototyping

- Flexible small-batch assembly

- Real-time DFM feedback

PCBasic’s high-mix/low-volume workflow is built specifically for rapid engineering validation (EVT), design verification (DVT), and testing.

3. Smooth Transition to Mass Production

Many factories can make prototypes. Very few manage the transition to 10,000+ unit batches without delays or yield fluctuations. PCBasic solves this gap through digital MES, component traceability, and stable SMT lines that maintain the same process parameters across batches.

PCBasic’s One-Stop Solution for IoT Companies

✔ Rapid PCB Prototyping

- Quick-turn PCB fabrication (as fast as 24H)

- FR-4, high-frequency, copper-core, multilayer, and HDI options

- Controlled impedance stack-ups for Wi-Fi, BLE, LoRa, LTE-M, NB-IoT designs

✔ High-Precision SMT for Micro Components

- 01005, 0201, 0.25mm pitch, micro-BGAs

- 3D SPI + AOI on every line

- Vacuum reflow & nitrogen reflow options

- X-Ray for BGAs, QFNs, and shielded modules

✔ Complete Turnkey PCBA

- Sourcing components from DigiKey, Mouser, LCSC, and authorized distributors

- Full BOM management & alternates recommendation

- Material traceability with MES+ERP+CRM data integration

✔ RF & Wireless Expertise for IoT Boards

- Antenna tuning support

- Grounding & isolation optimization

- Controlled-impedance routing and EMI reduction

✔ DFM + DFT Engineering Support

PCBasic provides early engineering guidance on:

- Pad design

- Solder mask clearance

- V-cut / panelization

- Test-point planning

- Thermal relief optimization

This avoids rework and speeds up EVT–DVT–PVT phases.

How PCBasic Ensures Seamless Scale-Up to Mass Production

When IoT startups transition from prototype to mass manufacturing, common issues include yield drops, unstable component supply, and inconsistent reflow profiles. PCBasic eliminates these risks through:

1. Digital Traceability via MES

- Every component, reel, machine, operator, and batch recorded

- Automated process parameters tracking

- Real-time alerts for solder paste, reflow curve, AOI defects

2. Nine Advanced SMT Lines for Large-Scale Output

- High-speed placement machines

- Real-time AOI feedback loop

- Automated material towers & X-Ray component counting

3. Strict Quality Certifications

- ISO9001

- ISO13485 (medical devices)

- IATF16949 (automotive electronics)

- UL-certified PCBs

4. Reliable Global Logistics

Whether it’s small-batch pilot runs or 50,000+ pcs mass batches, PCBasic provides stable timelines and export-ready packaging.

Why IoT Startups and Global Tech Brands Choose PCBasic

✔ Fast Turnaround for Prototypes

Speed determines the survival of early-stage IoT projects. PCBasic’s 24–48 hour prototyping helps teams validate ideas quickly.

✔ Cost-Efficient for Scaling

Digitalized production keeps yields high and costs predictable.

✔ Strong Support for Complex IoT PCBA

PCBasic understands RF modules, sensors, microcontrollers, power management, and mixed-signal layouts.

✔ One Supplier for the Entire Lifecycle

From EVT → DVT → PVT → MP, you don’t need to switch factories.

Conclusion: PCBasic Accelerates Your IoT Hardware From Concept to Market

IoT hardware development demands speed, accuracy, and robust mass-production capabilities. With strong SMT expertise, rapid prototyping services, turnkey component sourcing, and fully digitalized manufacturing, PCBasic provides everything an IoT team needs—from the first prototype to stable, large-scale shipments.

Whether you are building smart home devices, industrial sensors, wearable electronics, or wireless communication modules, PCBasic ensures your product reaches the market faster and performs reliably in the real world.