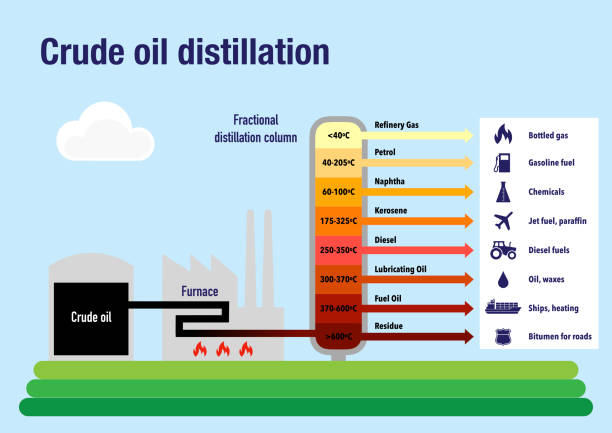

Burning fuel to create heat powers our world, from the boilers in large industrial plants to the furnaces keeping our homes warm. However, simply lighting a fire isn’t enough. To ensure that fuel is burned safely, cleanly, and cost-effectively, we rely on a technical procedure known as combustion process analysis.

The Importance of Combustion Analysis

In the past, technicians might have tuned a burner by looking at the color of the flame. A steady blue flame usually meant good combustion, while a yellow, flickering flame indicated trouble. While visual inspection is still useful, it is far from accurate. Modern equipment requires precise measurements to balance the ratio of fuel to air.

Combustion analysis provides that precision. By analyzing the flue gas (the exhaust), technicians can see exactly what is happening inside the combustion chamber. This data is vital for three main reasons:

- Safety: Incomplete combustion produces Carbon Monoxide (CO), a colorless, odorless, and deadly gas. Proper analysis ensures CO levels are within safe limits.

- Efficiency: If a system uses too much air, heat is wasted up the stack. If it uses too much fuel, soot forms and unburned fuel is wasted. Analysis helps find the “sweet spot” (stoichiometric combustion) where efficiency is maximized.

- Environmental Impact: Optimizing the burn reduces the release of harmful pollutants like Nitrogen Oxides (NOx) and Sulfur Oxides (SOx).

Key Parameters in Combustion Analysis

To understand the health of a combustion system, you must look at several specific data points. These parameters tell the story of how efficiently the fuel is being converted into energy.

Oxygen (O2)

Measuring the percentage of oxygen in the flue gas is the primary way to determine if the burner has enough air. A reading of 0% means there isn’t enough oxygen for complete combustion. However, a high reading indicates “excess air,” meaning the system is heating up air that is simply being vented outside, which wastes energy.

Carbon Dioxide (CO2)

Carbon Dioxide is a natural byproduct of complete combustion. Generally, a higher CO2 percentage indicates better efficiency, as it means the carbon in the fuel is being fully utilized. However, if CO2 levels drop, it usually signals that too much excess air is diluting the exhaust.

Carbon Monoxide (CO)

CO is the result of incomplete combustion. It occurs when the fuel doesn’t get enough oxygen to fully react. Even small amounts of CO can be dangerous. In a perfectly tuned system, CO readings should be near zero. Rising CO levels are an immediate red flag that the system needs adjustment or repair.

Stack Temperature

This is the temperature of the gases leaving the system. While the exhaust needs to be hot enough to rise and vent properly (creating a draft), it shouldn’t be too hot. Exceptionally high stack temperatures mean that heat is not being transferred to the water or air effectively, essentially throwing money out the chimney.

Draft

Draft refers to the pressure difference that moves the flue gases through the vent connector and chimney. Proper draft ensures that exhaust gases are pulled out of the combustion chamber and vented safely outdoors.

Tools and Technologies for Combustion Analysis

Gone are the days of wet chemical kits that required complex manual calculations. Today, digital combustion analyzers are the industry standard. These handheld devices use sophisticated electrochemical sensors to sample flue gases directly from the stack.

Modern analyzers offer real-time data, calculating efficiency automatically based on the fuel type selected (e.g., natural gas, oil, propane). Many advanced models feature Bluetooth connectivity, allowing technicians to send reports directly to a smartphone or printer. This technology provides a documented history of the equipment’s performance, which is crucial for maintenance records and liability protection.

Performing Combustion Analysis: A Step-by-Step Guide

Conducting a proper analysis requires a systematic approach. While specific steps vary by equipment type, the general procedure follows this path:

- Visual Inspection: Before turning on the analyzer, check the equipment for physical damage, soot buildup, or blocked vents.

- Startup: Fire up the furnace or boiler and allow it to reach a steady operating temperature. Taking measurements on a cold system will yield inaccurate results.

- Zeroing the Analyzer: Turn on the device in fresh air (outside the mechanical room) to calibrate the sensors to ambient conditions.

- Probe Insertion: Insert the analyzer probe into the test port of the flue pipe. It should be positioned in the center of the gas stream for the most accurate reading.

- Stabilization: Watch the readings. They will fluctuate initially. Wait for the numbers to stabilize, which typically takes a minute or two.

- Adjustment and Verification: Based on the readings (O2, CO, Temp), adjust the air/fuel ratio or draft as needed. Watch the analyzer to confirm the changes improve the readings.

- Documentation: Once the system is optimized, print or save the results for the customer report.

The Role of Emissions Tests in Orem

Combustion analysis isn’t limited to stationary boilers and furnaces; the same scientific principles apply to internal combustion engines in vehicles. In regions with unique topographies, such as the valleys of Utah, air quality is a significant concern. Pollutants from poor combustion can get trapped by the mountains, leading to poor air quality days.

This is why regulatory bodies enforce strict testing. For example, the role of emissions tests in Orem is critical for managing the air quality in Utah County. These tests utilize combustion analysis technology to ensure that vehicles are not expelling excessive hydrocarbons or carbon monoxide. Just as a boiler needs tuning to be safe, cars must meet specific combustion standards to remain road-legal.

This focus on analysis extends throughout the region. Residents and fleet managers operating nearby face similar requirements, which is why emissions tests in Provo are also a standard part of vehicle ownership in the area. Whether for a sedan or a factory, the goal remains the same: burn fuel cleanly to protect public health.

Benefits of Effective Combustion Analysis

Routine analysis offers tangible benefits that go beyond simple compliance.

- Reduced Fuel Costs: By tuning a burner to its optimal excess air levels, you can reduce fuel consumption significantly. For large commercial facilities, a 1% or 2% increase in efficiency can translate to thousands of dollars in annual savings.

- Extended Equipment Life: Incomplete combustion causes soot buildup, which acts as an insulator on heat exchangers. This forces the system to run hotter and work harder, leading to premature failure. Clean combustion keeps internal components clean.

- Immediate Troubleshooting: An analyzer can detect a cracked heat exchanger or a failing pump long before the system completely breaks down. This allows for preventative maintenance rather than emergency repairs.

Conclusion

Combustion process analysis is the cornerstone of modern thermal engineering and maintenance. It transforms the invisible chemical reactions of fire into actionable data. By monitoring oxygen, carbon dioxide, and temperature, we can ensure our heating systems and vehicles run safely and efficiently.